Greven 1978 Jumbo Amber Natural

Greven 1978 Jumbo Amber Natural

John Greven 1978. Jumbo in Amber Natural Finish.

2 Piece Spruce Top with Abalone Binding.

Solid Flame Maple Sides.

2 Piece Chevron Stripe Flame Maple Back with Abalone Inlays.

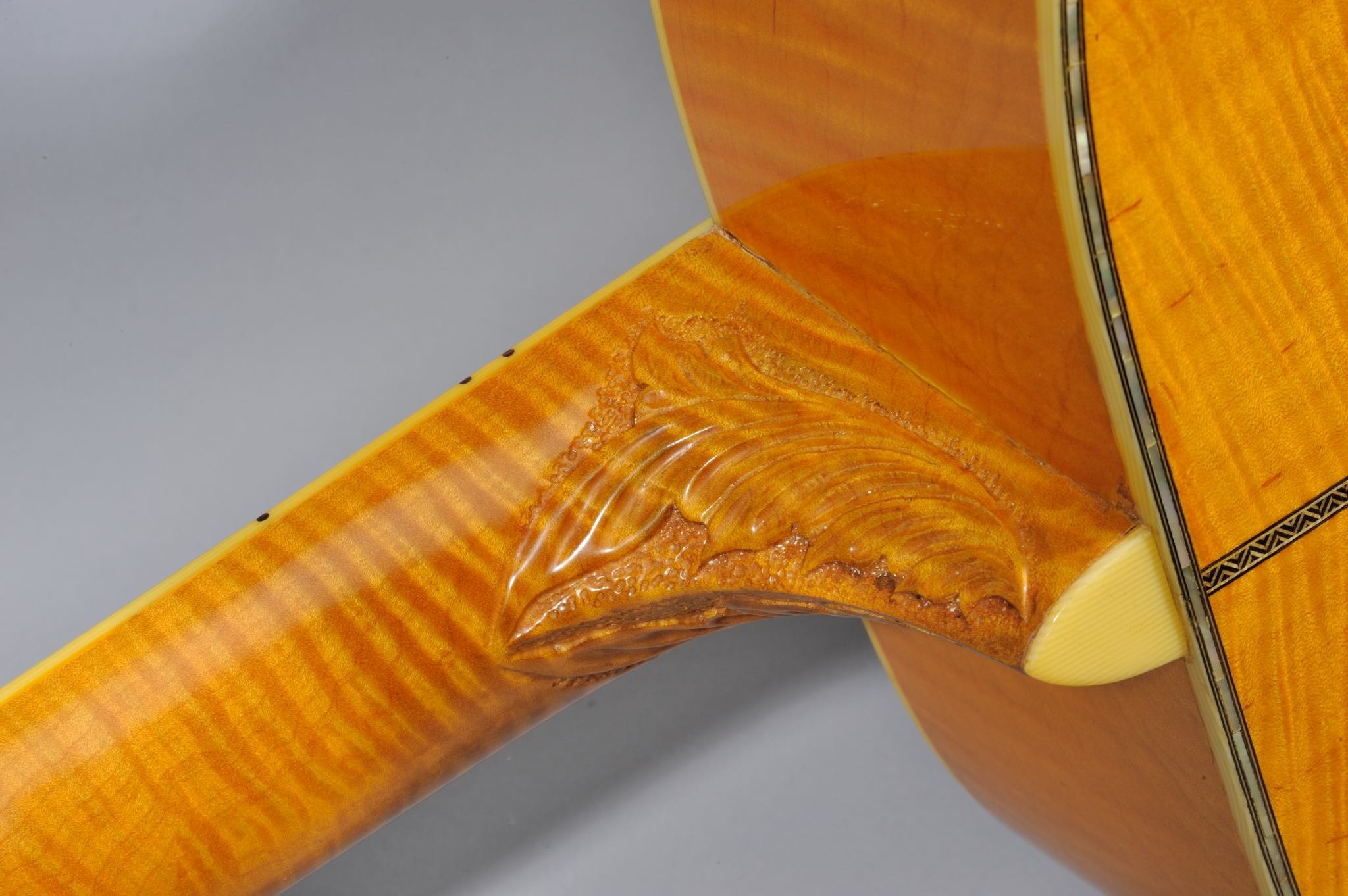

Tiger Stripes Flame Maple Neck with Sculpted Neck Heel.

Rosewood Fretboard with Custom Engraved Mother of Pearl Inlays.

Rosewood Bridge.

Headstock with Brazilian Rosewood Overlay Inlaid in MOP with the John Greven Logo & an Engraved Cartouche.

Full Binding on the Body, Neck and Headstock.

Tortoise Pickguard.

Sealed Gold Tuner with Brazilian Rosewood Tuning Pegs.

John Greven

From John Greven Website in his own words:

For the past 60 years, I have been creating custom instruments for a select group of musicians from around the world. They have come to appreciate the superior sound quality and ease of playing characteristic of my guitars. Where did it all begin?

Working for George Gruhn at Gruhn Guitars in the late 60's through the mid-70's repairing and restoring exceptional vintage instruments taught me what was possible. The experience gave me a direct measure of how the best of the vintage instruments compare to their modern counterparts and was the primary impetus for me to go into full time guitar making. I knew it was up to the small shop builder to bring back the big pre-war sounds. This has been and still is my life's goal as a guitar maker. I believe it possible to recreate not only the look and feel of the originals, but the sound as well.

PHILOSOPHY

My goal has been a simple one; build the best sounding, easiest playing, most powerful guitars on the planet. Fortunately, 60 years of building and 2200+ guitars provided me with the experience to do just that. It also allowed me to voice any instrument to fit the specific needs of the player through wood choices, construction details, and body styles.

While shop foreman at Gruhn Guitars in the early to mid-1970's, I was fortunate enough to work on some of the finest vintage guitars ever made, in particular Red Smiley’s pre-war D-45 and Charlie Monroe’s pre-war D-45. Both guitars are iconic in their tone and power. Their sound haunts me to this day and is, in my mind, the “holy grail” of guitar tone. It is this sound which forms the basis of the Greven sound.

I looked for materials that would give me the voice I seek, but more than materials alone, I have built very much like Martin and Gibson did in the early 1930's; light, strong heavily scalloped bracing, low body mass, and thin, flexible finishes. My guitars are “modern” where modern adds to the function without impacting tone, but the feel and sound is every bit “vintage”. Powerful over the entire range of the fingerboard, deep and rich texture to the voice, responsive to a fault are all descriptive of my guitar sound.

Published in Frets Magazine / June 1979

Frets visits….Greven Guitars Nashville, IN

By David McCarty, staff reporter for the Indianapolis News.

JOHN GREVEN, the founder, owner, and guiding light of the Greven Guitar Company, is a craftsman whose skills rival those o f the best instrument builders of all time. His beautifully decorated instruments have also earned him a reputation as a master of the art of pearl inlay. Ten years ago, in the spring of 1969, Greven was building a few guitars, making some banjo necks, and doing instrument repair work in Chattanooga,Tennessee.George Gruhn, then of GTR Guitars in Nashville, often passed through Chattanooga looking for vintage instruments. Gruhn was impressed with Greven's skillful and conscientious repair work and asked John to come to GTR to work as a repairman full time. John didn't want to move to Nashville, but after Gruhn made a few more visits and guaranteed a good salary, John was persuaded to change his mind. He moved to Nashville in June 1972. John worked as a TR repairman for almost six years, doing general repairs as well as inlaying and other custom work for such artists as Steve Stills, George Harrison, Buffy Sainte Marie, Steve Martin, JohnMcEuen, and Johnny Cash. But Greven wasn't content to remain someone else's repairman. Artist that he was, he couldn't be happy catering to other people's demands. He wanted to build his own guitars."It dawned on me," he says, "that, in the long run, if I was going to make a living and be something other than a repairman for the rest of my life, I'd have to make a move." In the spring of 1975, a representative from a Minneapolis guitar store was so delighted with some guitars Greven had built that he asked John to supply three to ten per month. "I just laughed," Greven recalls, "and told him there was no way I could build even two a month while I was working at GTR." But the representative persisted, and that got Greven thinking about starting a guitar company of his own. With that obective in mind Greven began building guitar molds, templates, and tools in his spare time. He finally left Gruhn's employ in 1977. For a while he continued to do some repair work for GTR, but he found that building guitars and repairing broken instruments just couldn't be effectively combined. "It's much more fun to build your own instruments; doing repairs is too much like work," he jokes. "It's a fulfilling experience to restore a guitar. It's also a lot of headache. Who wants it?"

The Greven Guitar Company started slowly. Greven's Minneapolis guitar connection folded, due to some impropriety at the dealer's end, leaving him with no place to sell his guitars until Gruhn again came to his aid and became his dealer. The location of Greven's Nashville shop, moreover, didn't exactly promote walk-in trade. It was next to a pornographic movie house and just downstairs from a massage parlor. The shop had also been burglarized many times. John and his wife, Celia, didn't feel that the downtown environment was really a suitable place in which to start a new business, much less raise their young daughter, Rachel. Celia suggested that they move back to her home state of Indiana. Ironically, the move took them from one Nashville to another. They bought a home with an adjoining shop in the small rural community of Helmsburg, nestled in the rolling wooded hills outside Nashville, Indiana. Nashville is the center of the popular Brown County tourist area, just a few miles from Bean Blossom, the site of Bill Monroe's famous Brown County Jamboree.

Once established in Indiana, Greven devoted himself to building nothing but the best guitars he could. His work at GTR, and his association there with Randy Wood (the "R" i n GTR), had given him the opportunity to study at first hand both the good and the bad aspects of various techniques used by the famous makers. "Our guitars try to emulate the best guitars I've seen, Greven proudly says today. "When I got into this, I wanted to build a new guitar that was 40 years old, and I wanted it to play and sound like an old Martin. Of course, the more I developed my own techniques, the more my guitars came to sound and play like my guitars. Each of Greven's different models has a characteristic "Greven tone." "Ultimately," John says, "we're looking for a particular sound and feel to our guitars. " To achieve those ends Greven continually experiments with his designs. One innovation is the use of side braces at the waist of his guitars. He feels that this provides better protection against splitting of the sides than does the use of the more common glued strips of cloth. He also feels that the braces stiffen the sides and allow the top to vibrate more freely. "We're trying to get to the real meaty, ballsy sound of an old Martin, " says John of his experimentation, "and I think we're getting pretty close; but we'd also like a balance. We want to get kind of a hybrid between a really crunchy old herringbone Martin sound and a nice, sweet, well-balanced sound."

Greven feels that there is a definite relationship between the stiffness of the top and the quality of a finished guitar's sound. "The stiffer it is, the better the highs," he says. "The trick is to build a top that is both stiff and limber, to get both the highs and the lows. That's why the braces are where they are and how they're shaped. If you scallop the braces you lower the fundamental. Every brace has its own fundamental frequency. Each brace vibrates in a certain pattern, and when you shave off the middle it makes the brace more limber in the center and stiffer at the edges, consequently lowering the fundamental. It makes the top more limber in that area. It's kind of how you control your bass end." But in his own work Greven has gone from regular bracing to scalloped bracing and back; he feels that the sound of the top depends on its overall stiffness in relation to the stiffness of the bracing. He carefully checks the stiffness of each piece of top wood before cutting the braces to match, shaping and changing each brace individually.

For his tops, Greven uses Sitka spruce and German silver spruce or occasionally cedar, depending on the sound that a customer wants. The tops are graduated (even though Greven's guitars are flat-tops) from 1/8" thickness under the bridge to as little as 1/16" thickness near the sides. While other guitar builders experiment with bizarre braces in flying buttress designs or in the shape of I-beams, Greven forsees no radical changes in his own construction or bracing patterns. "I think there's a definite limit to what a guitar of a given size and shape is going to sound like," he says. "I don't think radical bracing is going to change things enough to make it worth the effort." Greven offers a selection of eight distinct body shapes, each available in a variety of combinations of woods, inlay patterns, carvings, and finishes. John is thus more of a custom builder than he is a mass manufacturer. He typically uses Brazilian rosewood or curly maple for his guitars' backs and sides, but he has also used East Indian rosewood and other rare woods on occasion. Though he feels that Brazilian rosewood is better than East Indian rosewood, Greven doesn't believe that rosewood is the ultimate material for guitar bodies. "I'm almost convinced that good curly maple is superior in tone qualities to Brazilian rosewood," he says. "So few people have built good curly maple guitars that it's hard to tell. The instruments haven't been around long enough."

Greven and his assistant, Ron Volbrecht, currently build about three to four guitars per month. Greven would like to hire a third assistant eventually and expand production to 10 guitars a month. But that would be the limit. "If you get too many people, you tend to deal more with the people than with the product," he says. "Td rather have my hands in the guitars than in other people's affairs. I don't see going into production with a 15-man shop. Making one hundred or four hundred guitars a year is not worth that to me. I don't want that kind of headache. I've seen too many people go down the drain that way. Id rather stay small and cozy and build up a very personal trade with all the people I deal with. It's a lot more fun."

Greven says that his production techniques have become so efficient that he can build a dreadnought-sized guitar that sells for only about $650. He maintains a delicate balance between producing enough guitars to make a decent living and upholding the strict quality standards he demands. "I’d like to build two a month and make a living at it," he says, "but we're not able to do that." The demand for Greven guitars has skyrocketed. The company had a two-month backlog in late 1978; it has a six-month backlog today. Greven's guitars may be good when they come out of the shop, but they improve still further with age and become, as Greven says "boomers." He feels that two key factors contribute to the improvement of a guitar's sound as it ages: "As the wood continues to dry out, the guitar gets a warmer, mellower tone. But what's more important is how the guitar is used, how it's played in.' If it's a good guitar to start with, it'll be a great guitar once it's played-in." Greven feels that the kind of music played on an instrument has a great influence, too. "We had an F-style leave the shop about two years ago," he recalls, "and it was an okay guitar. The fellow who bought it played bluegrass lead, then jazz, pop, and even rock, so the guitar got played all over the neck. Now it's one of the most amazing guitars I've ever played. It's kind of a legend in the Detroit area because so many people have played it and been blown away by it." The caliber of Greven's pearl inlay work is also legendary. [Ed. Note: A story about Greven's inlay techniques appeared in the Oct.’75 issue of FRETS's sister magazine, Guitar Player] His reproductions of antique inlays are often "tighter" and better executed than the originals. His own designs have a charming grace and fluidity. "I’m more interested in novelty of design, in getting a whole new kind of inlay approach to my guitars," John says, "I think the customer appreciates that. I've been doing that kind of stuff so long that the mechanics don't really mean much to me; the aesthetics of it, how things work together that's where I'm concerned." He uses each piece of pearl carefully, deliberately working the grain and color markings into the inlay design. Greven employs many inlay materials: white mother-of-pearl, green or red abalone, Tahitian pearl (which is gray), and snail shell (which is mostly pink). Besides shell materials, Greven has used inlays of silver, copper, and brass to complement his designs. Once pearl is inlaid into the fretboard or headstock, Greven carefully engraves the detail and relief lines into each piece, bringing the cold material to life. He uses Black Background Compound (a jeweler's preparation available from Paul H. Gesswein Co., 235 Park Ave., South, New York, NY 10003) to fill in the lines, making them stand out boldly against the light pearl. Greven says that this material not only leaves a better line than India ink, it also resists string friction better, making the inlay design more durable. Beyond his dedication to making superior guitars that please both the ear and the eye, Greven is intent on selling his instruments for what he considers to be a fair price. "We have quite a low overhead and intend to keep it that way," he says. "I like to pass that onto the customer. I'd feel badly about charging more." Clearly, John Greven is a master craftsman of the old school.

PUBLISHED in ACOUSTIC GUITAR, DECEMBER 2002.

By David McCarty, staff reporter for the Indianapolis News.

If you can judge a luthier's work by the company he keeps, then John Greven is nearly in a class by himself. During the course of a career spanning more than 25 years, Greven has produced exquisitely handcrafted and inlaid acoustic guitars and other instruments for such stars as George Harrison, Eric Clapton, John Denver, Stefan Grossman, John Hartford,Steve Martin, Stephen Stills, Johnny Cash, and Mary Chapin Carpenter (who just ordered her third Greven guitar).

An East Coast native, Greven built his first instrument—a five-string banjo while attending high school in Moorestown, New Jersey. By 1967, he’ d moved to Ithaca, New York, to work in a music store and build custom steel-string guitars. Two years later, he moved to Chattanooga, Tennessee, and began building guitars with luthier John Davis. That experience brought him to the attention of vintage guitar guru George Gruhn. Admiring Greven's remarkable artistic skills and superior craftsmanship, Gruhn asked the young luthier to move to Nashville, Tennessee, and become chief repairman at GTR, which soon became the world-famous Gruhn Guitars. Working behind the repair bench at Gruhn's shop, Greven had the chance to observe, measure, and work on some of the finest acoustic guitars ever made, as an endless parade of herringbone Martins (including D-45s owned by Charlie Monroe and Red Smiley), prewar Gibsons, and other choice instruments came through the store for repair, appraisal, or sale. "My exposure to so many of the best guitars on the planet created an ultimate sound' in my head that I now refer to every time I make a guitar," Greven explains. "That sound is the ideal I try to achieve in each of my guitars. Over the last few years, I've really learned how to do that consistently. What I'm able to build now is a direct result of having played and worked on those amazing vintage guitars early in my career."

By 1976, Greven tired of life in big city Nashville, so he and his wife, Celia, and daughter moved to a much smaller Nashville in Celia's native state of Indiana. Located in the rustic, wooded hills of Brown County, Indiana, Nashville, Indiana, proved an ideal place for Greven to start his own custom guitar company. Working out of a converted garage outside his splitlog home, Greven honed his production techniques and perfected his guitar designs, basing them on the proven designs of American mass-manufactured acousticguitars, infused with his own creative insight and sparkle. After living and working in south-central Indiana for more than 20 years, Greven decided in the late 1990s to move to Portland, Oregon. The beautiful West Coast city affords him access to superb guitar-making materials and proximity to his daughter, who lives in Seattle. Today, his tidy, perfectly organized shop occupies about 1,000 square feet in the basement of his home (Greven Guitars, 1906 SE 42nd Ave., Portland, OR 97215; phone/ fax [503]233-8525; www.grevenguitars.com). Each of his construction processes occupies a specialized workbench. "I have really simple tooling," he says,"a belt sander, drill press, band saw, routers, things like that. I've been doing this for so long that I can be very efficient and double upon batches." Greven now produces about 50 guitars a year aimed at both flatpicking and fingerstyle players. He offers Martin-inspired models like the 00, 000, and D dreadnought and Gibson-based models like the Jumbo (based on the J-185) and Super Jumbo (based on the J-200), and a new Larson Brothers-inspired Prairie State Jumbo. He's also created an expanded 000 model called the F and a 12-fret, slope-shouldered version of it called the FX. The 00, 000, F, and X models are all available with either 12 or 14 frets clear of the body. He builds his guitars with flamed maple, various species of rosewood, Engelmann and Adirondack spruces, and other choice tonewoods. But Greven has also always experimented with unique tonewoods such as Peruvian cherry and champagne bubinga, and lately he has been building guitars from lacewood. "To me, they sound very much like prewar Martins," he says of guitars made from this exceptionally stiff material. "They have a powerful bottom end and a ballsy presence. In density, it's like mahogany, but it's as stiff as stainless steel. It gives the guitar a rich, complex sound with screaming trebles and a huge bass response." He's also recently begun using Madagascar rosewood as a replacement for the nearly unobtainable Brazilian species. " I think tonally it's just as good," he contends. Greven's experience working with vintage guitars gives him the ability to tailor each instrument to the needs of the individual customer. "By tweaking the top, you can adjust the sound to suit the customer. To get a new instrument to sound like an old instrument, the top can't be too stiff or too limber," he says. It's a matter of gradually thinning it to the edges so it can vibrate very easily, especially in the lower frequencies. My braces are patterned after a mid-30s’ Martin with a small footprint for the braces, which are heavily scalloped depending on what the customer wants." Greven is one of the premier inlay artists in the world, and his guitars are as well loved for their beauty as their sound and playability. Using herringbone and pearl binding as well as green heart abalone, blue oyster, smoky pearl, and other exotic materials, Greven transforms his guitars from utilitarian instruments to true works of art. "Lately, I've gotten into almost a photo-realistic style of inlay, doing less traditional things," he explains, adding that his Japanese customers still prefer the heavily ornate White Lady and Presentation models, which include ornately carved heels. A constant tinkerer and experimenter, Greven has also developed a unique synthetic tortoiseshell material called Tortis, which he uses on pickguards and peghead overlays. The material also makes excellent flatpicks that nearly duplicate the sound of natural shell picks. Prices for a Greven custom instrument range from $2,500 to $4,000, although his fanciest Presentation models go for upwards of $7,500. "I try to keep my guitars affordable,"he says. "I'm a strong believer in that."